Cutting to length is the technology of cutting a metal strip into metal sheets.

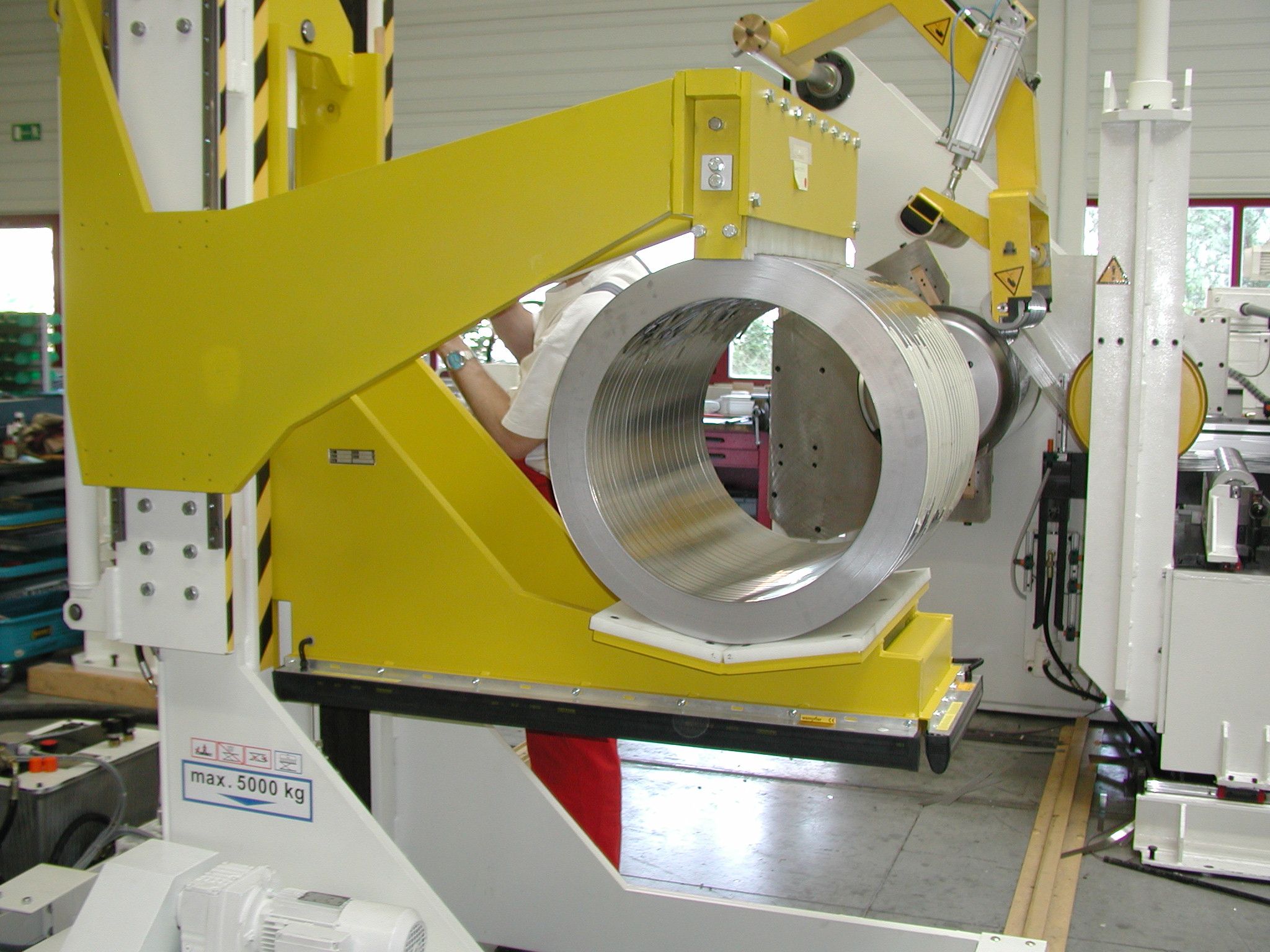

b+s cut-to-length lines are used to cut metal strips into sheets and then stack them into packages.

Depending on the requirements and productivity, our cut-to-length lines are equipped with fixed cut-to-length shears (stop and go) or with flying cut-to-length shears and the appropriate stacking system.

Depending on the required quality, flatness and surface of the metal sheets, the cut-to-length lines are equipped with our SCHNUTZ precision levelers, trimming shears or a foiling device.

Line Specification

Our services include:

- detailed project consultation

- customer-oriented kick-off meeting

- in-house design office

- intensive interaction between mechanical and electrical design

- high value-added chain with in-house manufacturing and assembly

Advantages of a b+s cut-to-length line:

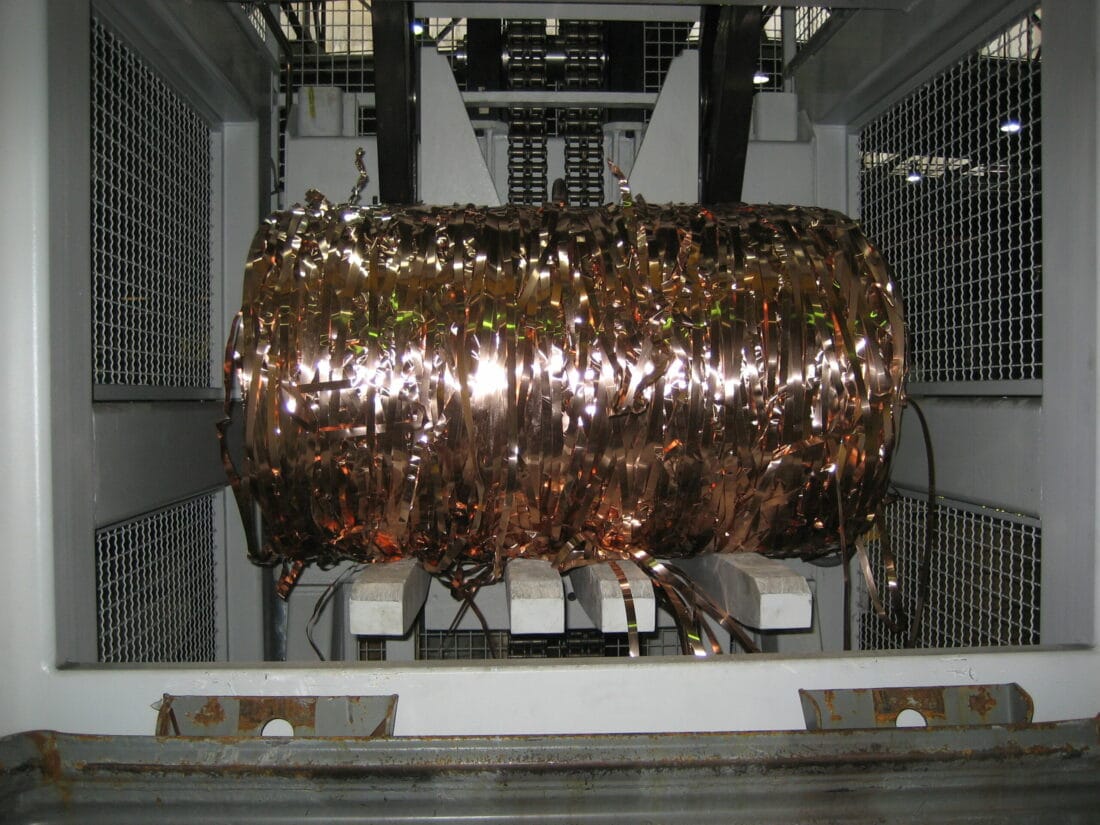

- strip flatness is guaranteed by the integration of a high-performance leveler from the wold market leader SCHNUTZ

- Elimination of strip imperfections through the use of “4-high”, “5-high” and “6-high” levelers

- reduction of set-up times through innovative automation solutions as well as high line speeds

- high-precision cut quality and angularity of the blanks

- Strip processing with integrated trimming shear and scrap disposal systems, such as scrap winder or scrap cutter,

- high-precision stacking accuracy and no surface damage due to advanced stacking systems,

- experience in processing ultra-high-strength materials with tensile strength above 1,500 N/mm² and yield strength above 1,100 N/mm².